Xiao Xing is a petrochemical worker who is mainly responsible for the company's container procurement and maintenance work on weekdays. Someone approached him to inquire about Fran's information, and he can be said to be very familiar and knowledgeable; And the maintenance and upkeep of flanges is also a subject of study!

A flange, also known as a flange plate, is also known as a protruding edge; The English scientific name is Flange. We often see flanges used in water pipelines, oil and other media pipelines. Because not only the pipeline is sufficient, it also needs to be connected to form a precise structure for use.

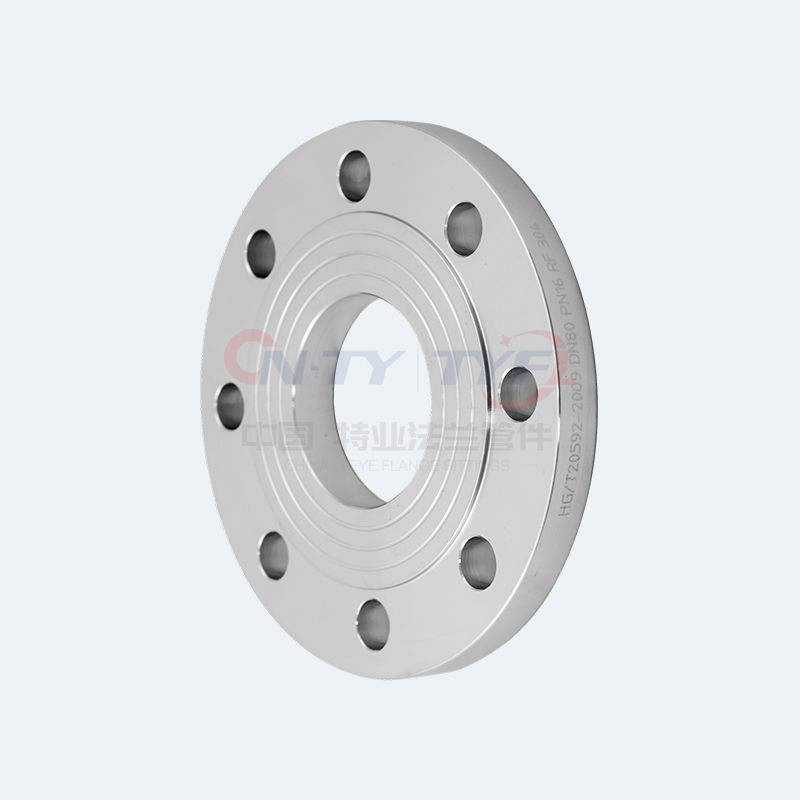

What is a flange? The transliterated engineering name is to fix two pipes or equipment on a flange plate, and then place a cushion to tighten it into a flange tool. It is high-density, easy to disassemble, and easy to use, and plays an indispensable role in engineering projects!

We can see that flanges are divided into flange fittings, threaded fittings, and socket and spigot fittings based on their unique connection methods. The quality of the flange must meet the standard, otherwise it will deform and the thickness must be moderate. Too thin can deform, and too thick is not easy to process! The thickness will be customized according to the requirements here, but it is usually between 4mm and 200mm. Even some large flanges can have a diameter of over 4800 millimeters.

If you are working on an engineering project for a high-end client, the requirements for flanges are very high when designing steel pipes for houses. Sometimes, you may feel frustrated due to the company's shortage of flanges. Some pressure vessels require built-in container flanges, such as filters, towers, etc. Especially when designing water pipelines, pressure and sealing should be considered. If the flange is not properly selected, it can easily cause danger, such as leakage in high temperature, high pressure, or even highly toxic media. Generally, when doing engineering work, it is necessary to fix two pipes, fittings, or appliances on a flange plate, and then place a flange pad in the middle. Double protection is achieved by fastening with bolts. Under high pressure, flanges not only require wear resistance but also corrosion resistance, thus requiring very high composition requirements.