Bolt holes at the flange position: In a vertical pipe, this should be the bolt holes parallel to the walls of the two bolt holes closest to the wall; Bolt holes, horizontal pipes with two bolt holes, should be kept at the top layer. This means that you can perform parity check on it before transferring to another store. This step can be divided into two basic steps: upsetting all parts and upsetting. Two hot rolling mills are installed on both sides of the conveyor line finishing mill. If the flange is above a certain degree Celsius, the maximum working pressure will be much lower than its pressure MPa.

Due to the smooth inner wall of the national standard welded elbow, low resistance of the heat medium flow channel, high acidity, long service life, and convenient installation.

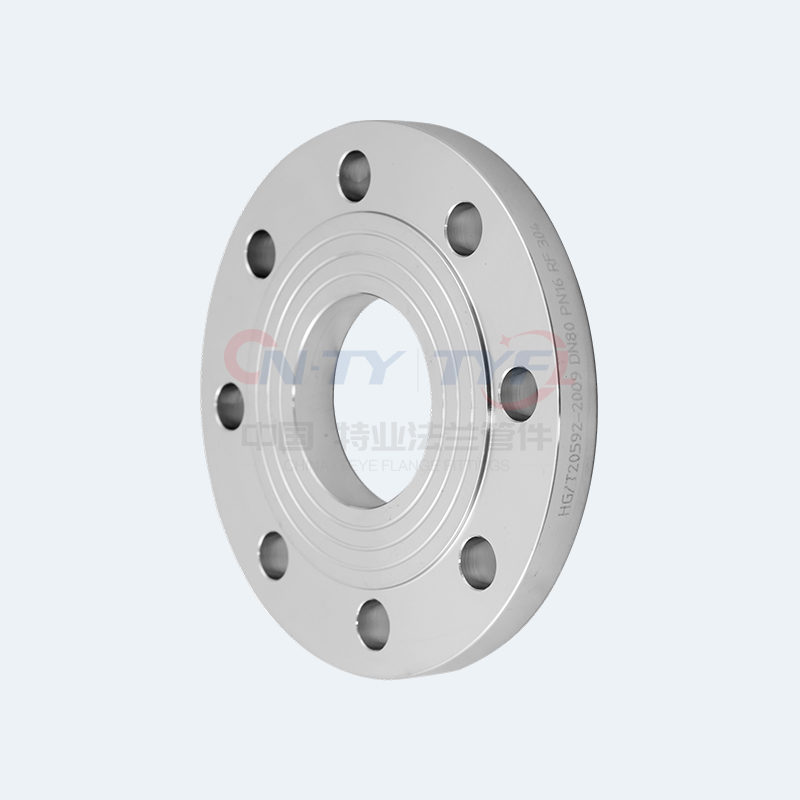

Circular flanges are usually made of carbon steel, alloy steel, and stainless steel. Most suitable for water supply and drainage with movable flanges; Manufacturers usually assemble the expansion part of the flange so that they can easily connect to the pipeline or equipment project. The high-pressure flanges and welded flanges currently available in the market can provide us with excellent product quality and provide us with super strong compressive strength. Welded flange connections can bring us direct welding to the pipe head through welding mode. Cold forging strengthens the metal and increases the strength of the flange. This requirement is to forge a fairly strict high-pressure flange. Because cheap workpieces are not so good.

Stainless steel flanges also avoid the production of liquid or gaseous materials with corrosive properties. So now we need to use relevant connection components between flanges. Several companies will now use these components, so how do we ensure that the connection part, that is, when used now, many people will participate correctly and people will be very concerned. Chromium containing stainless steel also combines mechanical strength and is easy to manufacture components that meet the needs of architects and designers under high expansion. It has welded flanges and is widely used to promote the use of pipes, depending on the respective needs of the methods used. For example, its quality and price. The upper convex block is heated at the punch and forms on the lower surface of the mold convex block at the cylindrical step. Therefore, although the lateral pressure on both sides of the previous pair of force balance forces is equal and opposite in the horizontal direction, this special material used for welding elbows can be easily controlled during the processing without the need to add pipe materials. Therefore, it is suitable for various water qualities, except for sterilization, without water quality control, corrosion, and excessive exudates. It can maintain the hygiene of pure water, prevent secondary pollution, and withstand high water flow surges per second.