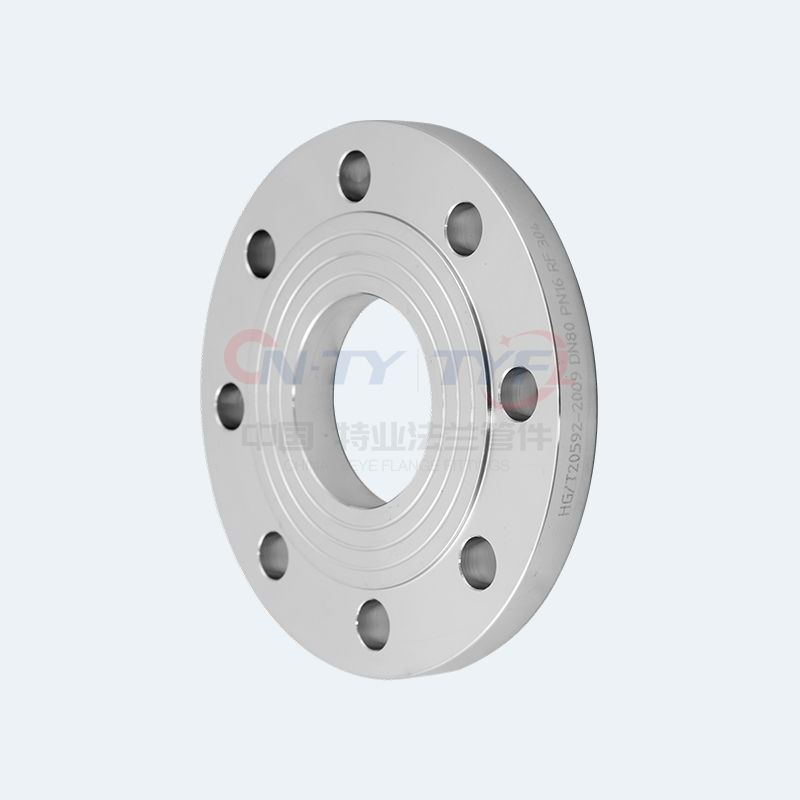

We all know that flanges are a pipeline tool that can be seen everywhere, but how to stop the correct processing of flanges? Today, the editor will tell you about flange processing, making the industrial industry not a secret.

In daily large-scale processing, look! We will see the process of consuming flanges. The common flange processing technology is to manufacture different required accessories from the steel of the circular ring shell. The materials used in practice can demonstrate important characteristics. This process is suitable for manufacturing flanges of any size. It is an ideal method for manufacturing large carbon steel flanges.

What is carbon steel?

What is carbon steel? It mainly refers to the stability factor of its mechanical properties. Whether the flange is stable or not depends on the carbon steel content. Usually, it involves a large amount of alloy elements, and the flange is correspondingly more stable. Sometimes referred to as ordinary carbon steel or carbon steel. The heating temperature of the flange is determined by the tolerance of the data. Usually, the higher the heating temperature; The higher the high-temperature tolerance of the data, the higher the heating temperature. If the pipeline size is too large, it is difficult for us to purchase suitable materials for splicing, and we can only use welded flanges. Due to the presence of this content, it appears that the flange is not easily corroded.

Our company is a professional pipe fitting manufacturer with over a hundred engineers! This also includes senior engineers. What do you care about, the company's equipment issues? Notify everyone that the company has advanced pipe fittings and flange matching consumption lines; Whether it is forging, mechanical processing, cold forming, hot extrusion, heat treatment, etc., all meet international standards, and corresponding physical and chemical testing is available. Our company has also introduced the world's most advanced physical and chemical testing equipment and technology. The well-known optical frequency instrument can quickly read the instrument.