The company has entered flange, but I don't know how to classify it? What can I do with different sizes and profiles? The following article may be helpful to you.

The flanges of flanges can be classified into carbon steel, cast steel, alloy steel, stainless steel, copper, and aluminum alloy flanges according to their categories; According to consumption methods, it can be divided into forged flanges, cast flanges, welded flanges, and rolled flanges (oversized models); If flanges are manufactured according to manufacturing specifications (Ministry of Chemical Industry specifications, petroleum specifications, electrical specifications), American specifications, German specifications, Japanese specifications, Russian specifications, etc.

What is the composition of the flange connection? How many joints are there? Is there a washer? Nut?

The correct answer is that the flange (joint) consists of a pair of flanges, washers, and several bolts and nuts. What is a gasket? It can be used to reduce gaps and can be placed between two flange sealing surfaces. Compare the flange according to the request, and then tighten the nut. When the specific pressure on the outer surface of the gasket reaches a certain pressure value, it can fill the unevenness on the sealing surface and make the joint tight.

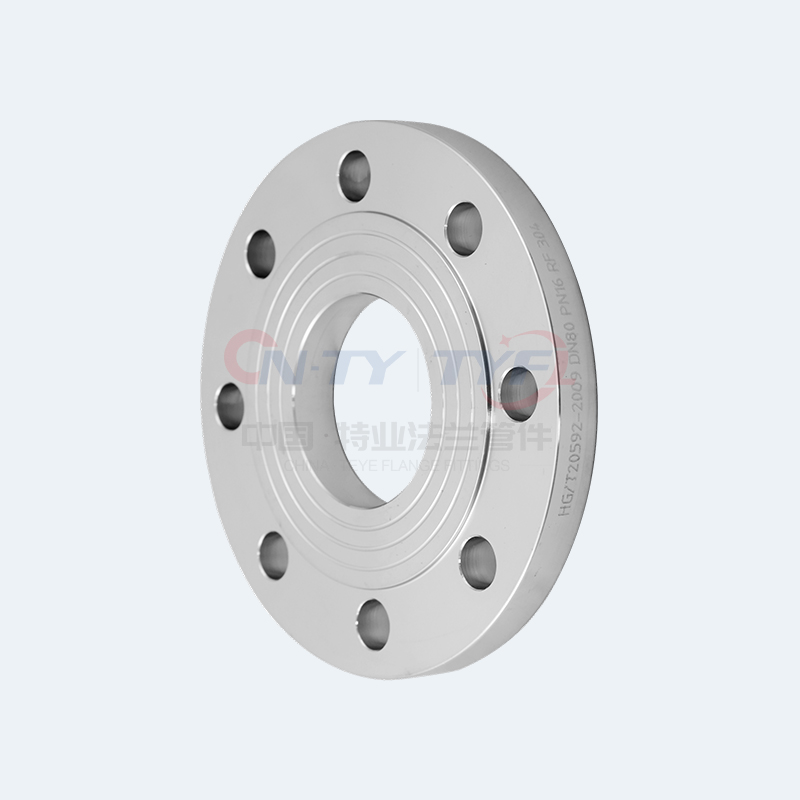

What is the composition of flange connection? The flange joint is a detachable joint. According to the local connection, it can be divided into container flanges and pipeline flanges; According to the type of construction, there are integral flanges, curved needle flanges, and threaded flanges. Common integral flanges include flat welded flanges and butt welded flanges. Flat welding flanges have poor rigidity and are suitable for places with a pressure less than 4PA. Butt welded flanges are relatively rigid and suitable for high pressure and temperature environments.

The flange sealing surface is also very different, let me share with you: there are mainly three types of products; A common flat sealing surface, suitable for places with low pressure and non-toxic media; There are also concave and convex sealing surfaces! This analogy is applicable to high-voltage places; I have also seen groove sealing surfaces, which are usually suitable for flammable, explosive, toxic media, and high-pressure environments.

Simply put, flanges are the connections between shafts, which are used to connect the ends of pipelines. Of course, it is also used on the inlet and outlet of the equipment, for the connection between the two devices, such as the flange we see on the reducer.

Sometimes, flanges can also be seen on pumps and valves; When connecting to pipelines, a part of these equipment requires flange connection. For example, the connection of ventilation ducts can be referred to as "flange components". The connection between water pumps is called the "flange component" of the pump. Of course, smaller valves and other components can be referred to as "flange components".